Munich. The BMW Group is writing the next chapter in

the future of mobility – and #NEXTGen 2020 provides the ideal platform

on which to present this latest instalment. Following the highly

successful inaugural event in 2019, this year’s programme will be

staged in digital formats. In a world that is changing more radically

than ever, the BMW Group has set itself the target of continuing to

spearhead technological development, set trends and be an instrumental

force in shaping the future face of mobility with an attractive

product portfolio and its Power of Choice strategy.

At #NEXTGen 2020 the BMW Group will open doors that are normally kept

firmly shut. It showcases new technologies and vehicles, while also

looking at some very specific examples of what next-generation

mobility might – or will – look like. Indeed, as well as presenting

highlights from the Research and Innovation Centre (FIZ), #NEXTGen

2020 will host world premieres from the BMW Motorrad and MINI brands.

And the event will also take a look at the design of the

series-production version of the BMW iNEXT, which will go on sale in

late November 2021 badged as the BMW iX.

Oliver Zipse: “The BMW Group is constantly striving to

reinvent itself.”

A rapidly approaching future sets the tone for this year’s #NEXTGen

2020. Topic areas such as connectivity, electric drive systems,

artificial intelligence, international alliances and BMW’s new Driving

Simulation Centre provide an ideal introduction to the BMW Group’s

role in this dynamic climate. After all, they each form an established

element of the BMW Group’s day-to-day reality and are playing an

increasingly important role in the development of current and future

vehicles. The BMW Group isn’t just ready for the future – it is

helping to actively shape it.

“The BMW Group is constantly striving to reinvent itself – that is a

key element of our corporate strategy,” says Oliver Zipse, Chairman of

the Board of Management of BMW AG. “The BMW iX encapsulates this

approach in highly concentrated form.”

Production of the BMW iX will begin at BMW Plant Dingolfing in 2021.

On the one hand, it amalgamates all the developments, experience and

innovations accumulated by BMW in recent years in its capacity as the

leading premium provider in the field of electric mobility. But its

development also illustrates the crucial role already being played by

artificial intelligence (AI). At the current time, the BMW Group

employs AI in over 400 applications and in every relevant department

of the company, for example in development, sales/marketing and

production. It is also used for processing and interpreting large

quantities of data. AI forms the basis for automated driving and the

most natural in-vehicle operating experience possible.

Another major step along the road to future mobility – automated

driving – can only be turned into reality with the aid of technology

from a field in which BMW has played a pioneering role since the

1990s: connectivity. BMW already offers over-the-air software upgrades

and digital services for many of its models today. The BMW iX now goes

one step further as the first premium model to employ 5G mobile

technology. A multitude of extremely powerful sensors – ranging from

cameras to radar and ultrasonic units – coupled with numerous

different antennae, from Bluetooth through to 5G, and assisted by

artificial intelligence and Data-Driven Services convert the BMW iX

into a high-performance computer on wheels.

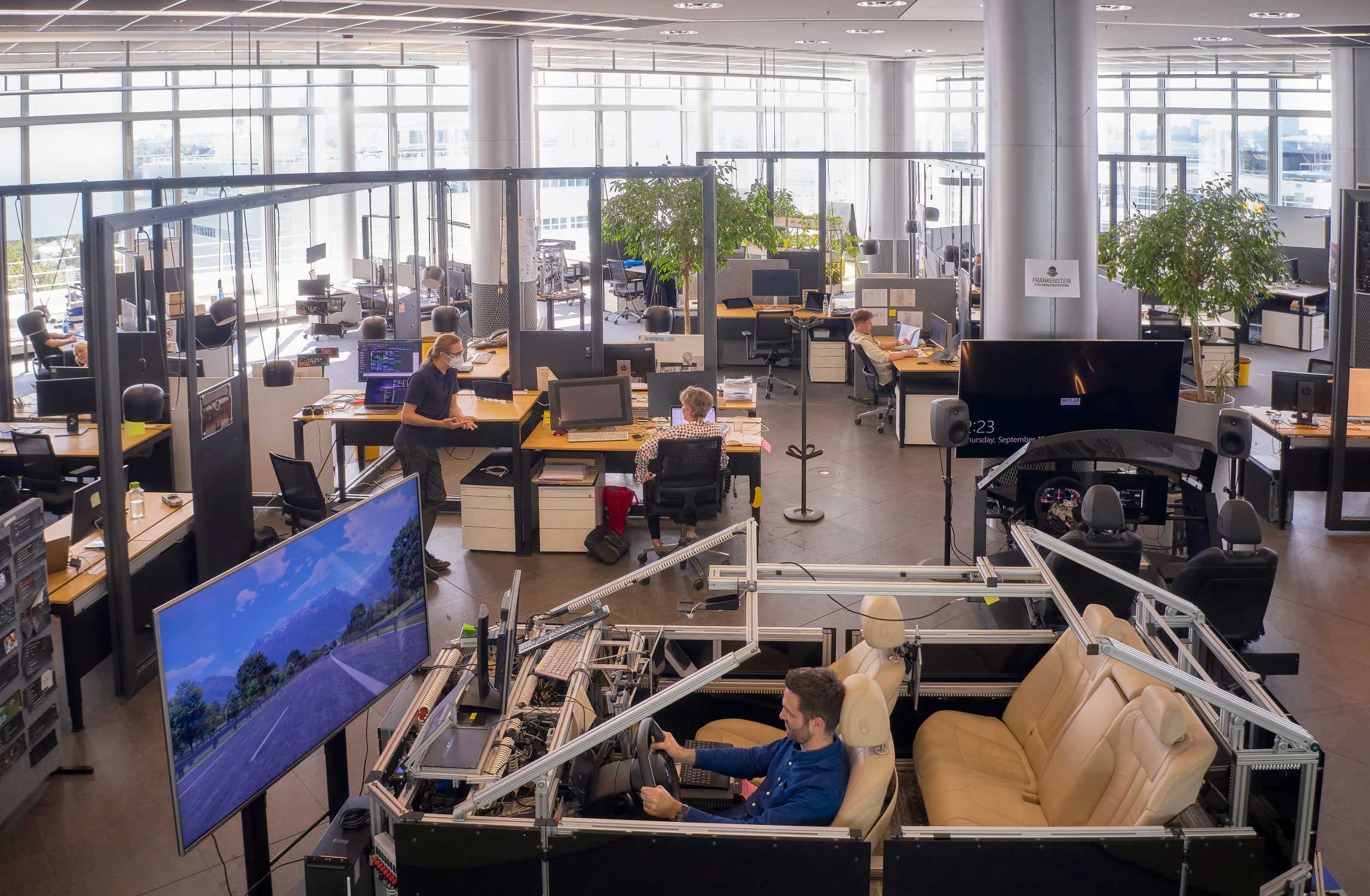

The BMW Group’s new Driving Simulation Centre in Munich provides an

ideal setting for these activities. The most sophisticated and

versatile facility of its type, this 11,400-square-metre facility is

home to a total of 14 simulators, including a high-fidelity simulator

and a high-dynamic simulator. These allow the experience of driving on

the road to be transferred to the lab in more realistic form than ever before.

International alliances open up new avenues.

The BMW Group’s alliances also highlight how determined the company

is to forge new paths. For example, the engineering tools used in the

past were no longer able to handle the complex requirements of the BMW

iX. This was one of the reasons why BMW contacted Epic Games back in

2015 and not long after became the first carmaker to implement a

mixed-reality system in vehicle development that had been created

entirely using components from the gaming industry. It is based on

Unreal Engine 4 from Epic Games.

World premiere for the MINI Vision Urbanaut.

When MINI presents the "MINI Vision Urbanaut" at 14:00 on

17.11.2020 at #NEXTGen , the brand will exclusively unveil its totally

new vision of space. There’s something to be excited about.

BMW Motorrad Definition CE 04 revolutionises the scooter segment.

Like the MINI Vision Urbanaut, the second model making its global

debut at #NEXTGen 2020 is also designed for purely electric travel.

The near-production BMW Motorrad Definition CE 04 scooter has evolved

from the BMW Motorrad Concept Link and merges the customer’s analogue

and digital worlds under the motto “Plugged to Life”. It offers city

commuters a means of transport and communication in one, with many of

the innovative elements and details of the BMW Motorrad Concept Link –

which was seen as a radical vision for the distant future back in 2017

– set to find their way into series production.

This clearly shows how far electrification of the entire BMW Group

model fleet has already progressed. And this is set to continue in the

near future. A quarter of all vehicles sold by the BMW Group in Europe

in 2021 are expected to have an electrified drive system, with this

proportion rising to a third in 2025 and half in 2030. In 2023, BMW

Group customers will be able to choose from 25 electrified models,

approximately half of which will have an all-electric drive system.

Modern leadership in many different areas.

At #NEXTGen 2020, the company is also exploring a variety of projects

that demonstrate the meaning of leadership today. A collaboration with

streetware label Kith in New York, for instance, allows BMW M GmbH to

detect the latest trends in a young and influential fashion scene. The

Electrified Wingsuit by BMW i represents a leap into a new dimension

in every sense. With the support of BMW i and BMW Group company

Designworks, Austrian Peter Salzmann used it to make the first ever

flight by a human wearing an electrically powered wingsuit. These are

just two examples of how the BMW Group is setting trends, picking up

on new developments and anticipating what customers want.

Electric drive system

.

BMW Group covers the entire process chain for electric driving

.

BMW has been the leading premium provider in the field of electric

mobility for many years now and has made a name for itself with

innovative vehicle concepts, such as the BMW i3 and BMW i8. The

company employs state-of-the-art production methods and facilities

across the board in order to offer the customer a well-balanced

product range whose drive systems – in keeping with the Power of

Choice approach – fit in exactly with their preferences and needs. To

further strengthen its leading position, the BMW Group is forging

ahead with the expansion of electric mobility and its model portfolio.

“The performance of our electric drive technology – now in its fifth

generation – has benefited from more than ten years of experience

through the BMW i brand across all areas: the high-voltage battery,

electric motor, battery cells, power electronics and charging

technology,” sums up Frank Weber, Member of the Board of Management of

BMW AG, Development. “This far-reaching expertise in all the major

components will allow us to further increase the number of electrified

models in our line-up to 25 in just over two years.”

Over a million electrified BMWs by the end of 2021.

It was the presentation of the BMW i3 in 2012 followed by its launch

just one year later that kicked off the modern era of electric

mobility at BMW. The groundbreaking electric car is also a fine

example of the advances that BMW has made in the intervening period,

as the storage capacity of the high-voltage battery in the BMW i3 has

doubled since its debut – without the battery taking up any more space.

Today, some 13.3 per cent of all BMW and MINI models newly registered

across Europe have all-electric or plug-in hybrid drive systems. The

BMW Group expects this proportion to already rise to a quarter by

2021, a third by 2025 and then half by 2030. BMW and MINI vehicles

with an electrified powertrain are now available in 74 markets around

the world. Total sales of electrified models in these markets had

exceeded 500,000 by 2019 and are likely to top the one million mark by

the end of 2021.

In-house developments from the BMW Group for all elements of

electric drive.

The BMW Group is relying on in-house developments for all elements of

BMW eDrive technology to help it fulfil these ambitious targets. The

quality of the electric motors, high-voltage batteries, charging

technology and power electronics is rooted in the experience garnered

with the BMW i brand since 2011.

The BMW Group will in future manufacture battery modules,

high-voltage batteries and electric motors for its electrified models

on eight production lines at its competence centre for electric drive

systems in Plant Dingolfing. The company plans to install a further

four lines over the coming years and ramp up production capacity

significantly. Having started with 8,000 square metres of production

space in 2015, the competence centre for electric drive system

production is set to grow tenfold to 80,000 square metres. The

objective is to produce electric drive systems for over half a million

electrified vehicles a year in Dingolfing alone as soon as 2022.

Dingolfing already boasts many years of expertise in the manufacture

of electric vehicle componentry – the high-voltage batteries for the

BMW i3 have been volume produced here since 2013 and the facility has

also been building electric motors since 2015. Today, Dingolfing

exemplifies the BMW Group’s Power of Choice approach; its innovative

production system allows plug-in hybrid and combustion-engined models

to roll off the assembly line here alongside fully electric models.

This makes the facility a prime case study in how to address the

diverse spread of mobility solutions and requirements in play today

and to come in the future.

BMW Group covers the entire process chain for electric driving.

The company’s equivalent to Dingolfing for battery expertise can be

found in Munich. The Battery Cell Competence Centre opened in 2019

maps the entire value chain of battery technology – from research and

development via composition and design to large-scale production. This

means the BMW Group is already developing forthcoming generations of

battery cells, focusing on customer-relevant aspects such as improving

energy density, peak output, service life, safety, charging

characteristics and performance at varying temperatures, as well as

cost reduction.

In 2022, the centre’s findings will be put into practice at the BMW

Group’s new pilot plant for manufacturing lithium-ion battery cells.

Currently under construction in Parsdorf near Munich, the facility

marks a decisive step in the company’s quest to continue strengthening

its position as the leading premium provider of electric mobility.

This pilot plant will make BMW the first carmaker to cover the entire

process chain for electric driving in-house.

The BMW electric powertrain strategy revolves around the Power of

Choice, i.e. providing the customer with the best and most appropriate

overall package for their individual requirements every time. As far

as electric mobility is concerned, this is primarily a question of

striking the perfect balance between performance and range. The

development of cutting-edge testing methods and test cases was an

important step along this path and has also led to increased

efficiency and faster processes.

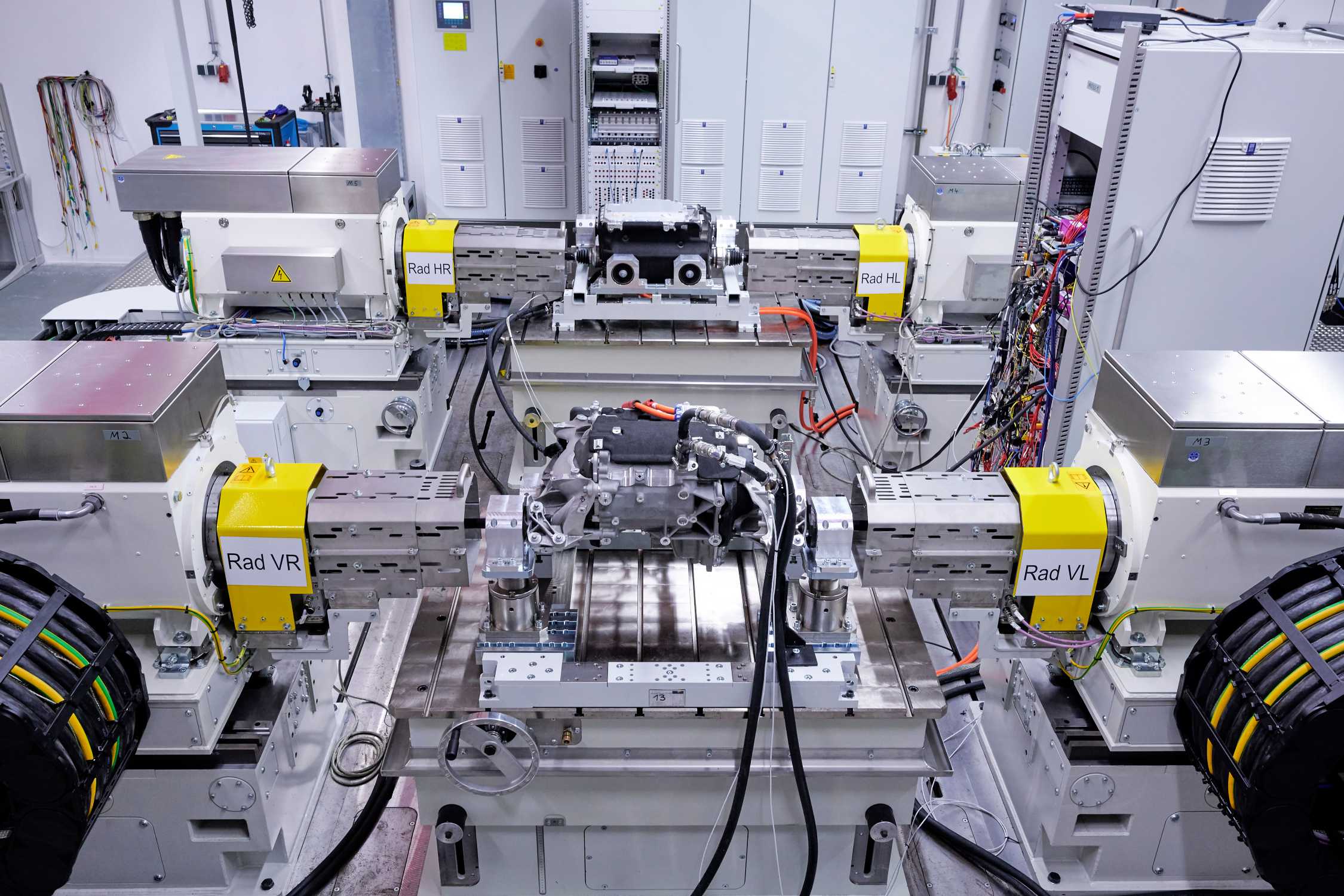

With this in mind, the BMW Group’s E-Drive system test rig in Munich

assists with the development of new system components from day one and

enables testing of any conceivable driving manoeuvre. To this end,

high-dynamic dynamometers can simulate any combination of rolling,

air, gradient, acceleration and inertial resistance in all manner of

different conditions – driving in sun, snow, wind, rain, through a

city centre or even on the Nürburgring-Nordschleife. And this can all

be done every day, round the clock. The facility even allows test

drives to be conducted remotely from the engineer’s home. So electric

drive system development work at BMW never stands still – and it is

getting faster all the time. The E-Drive system test rig plays a

central role here, helped by what is arguably its most impressive

feature: the ability to test parts that are not yet available in

finished product form by simulating them as virtual components.

Together with increased process efficiency, this serves to shorten the

development time for innovations by as much as one-and-a-half years.

Fifth-generation eDrive: major benefits for production and sustainability.

The fifth generation of BMW’s eDrive technology is now entering the

fray. Key advantages of this highly integrated electric drive

component include the absence of rare earths, a compact construction

resulting from the integration of electric motor, transmission and

power electronics into a single housing, and the flexible scalability

rooted in the technology’s modular design. The drive system is

compatible with all vehicle concepts and available in a range of power

ratings for different models. It will also feature in the BMW i4 and

BMW iX models from 2021.

In keeping with its status as a trailblazer for sustainability, the

BMW Group has signed contracts with its suppliers committing to the

use of green power only from now on in the manufacture of

fifth-generation battery cells. As production volumes increase, the

switch to green power will save around ten million tonnes of

CO2 over the coming decade. That is roughly the quantity of

CO2 generated by a city the size of Munich every year.

“The BMW Group is already working on the development of new vehicle

concepts that will help shape the future of electric mobility. Because

electric drive is not merely a technical innovation and a logical step

towards greater sustainability – it also has the potential to open up

a new dimension in driving pleasure,” says Martin Schuster, Head of

Development E-Powertrain. This is currently being demonstrated behind

closed doors by the company’s “Power BEV” experimental vehicle, as it

explores the limits of the technically possible. Three

fifth-generation electric motors producing a maximum system output of

over 530 kW/720 hp have been fitted in a current BMW 5 Series

production model. This trio of drive units were integrated without

encroaching on the passenger compartment and deliver extremely dynamic

longitudinal and lateral performance. The prototype is equipped with

two independently controllable electric motors at the rear axle. These

promise pure driving enjoyment thanks to their E‑torque vectoring

function, as electric drive brings a new and richly engaging angle to

the driving pleasure for which BMW is renowned.

Connectivity.

The ultimate in connectivity, computing power, data processing

and intelligence

.

The principle of swarm intelligence is best known from bees. The

individual members of a hive interact and communicate with one

another, cooperating as a single organism to also make intelligent

decisions, for instance when searching for a nesting site or the most

efficient route to a source of food. Such decisions based on

information from a swarm tend to be far more intelligent than those

taken by one individual on their own.

The same principle underpins a key aspect of connectivity at the BMW

Group. As Christoph Grote, Senior Vice President BMW Group Digital

Car, explains: Our customers already benefit directly from the swarm

intelligence of our connected fleet today. Smart vehicles use their

sensors to gather information on traffic, parking spaces, hazardous

situations or road signs, for example. This data is aggregated in

anonymised form in the BMW cloud and evaluated with the help of

machine learning. Relevant information is then fed back to the

vehicles, depending on the specific situation. This gives each

individual vehicle access to the collective knowledge of 14 million

others, and in some respects the swarm will know more than a human

possibly can.”

Digital vehicle platform.

It is the high degree of connectivity within the BMW vehicle fleet

that makes all the difference. BMW has over 20 years of connectivity

experience under its belt. The company installed the first SIM card in

a vehicle back in 1997 before going on to lay the groundwork for

connected, more individual mobility with BMW ConnectedDrive. Things

have progressed at a rapid pace in the meantime. The new digital

platform being introduced with the BMW iX sets new standards for

connectivity, performance and intelligence. When all vehicle functions

are active and operating at full load, the amount of data for

processing flowing through the car’s network is between ten and 20

times greater than in the current model generation, with data rates of

up to 30 Gbit/s. This is all made possible by the first ever use of

Gigabit Ethernet technology in a BMW.

To give an idea of its capabilities, the network aboard the BMW iX

can transmit the data stored on an entire DVD in a little over a

second. The growth in the volume of data is largely down to the

vehicle’s improved system of sensors and is needed for the driving

assistance systems.

A multitude of extremely powerful sensors coupled with over 30

antennae and the highly centralised architecture in which complex

software functions are concentrated in a handful of central

high-performance computers convert the BMW iX into a digital top

performer on wheels. It is the first model to feature this technology

toolkit, which paves the way for new and highly complex vehicle functions.

Connectivity as an enabler.

This all underpins extremely fast processing of the acquired data.

Part of the pre-processed data from the vehicle is transmitted to the

cloud at BMW, where the aggregated and anonymised fleet data is

analysed and evaluated with the help of machine learning. Relevant

information is then sent back to the vehicles, depending on the

specific situation, where it helps to increase comfort, efficiency and

safety for the driver.

Vehicles with On-Street Parking Information, for example, are already

capable of not just showing the driver where there is a parking space,

but also estimating the likelihood of it being available at the

calculated arrival time. Taking this data as a basis, the route

offering the greatest probability of finding a parking spot close to

the destination can be calculated for the remainder of the journey,

saving customers time and stress. At peak times, cars searching for

parking spaces account for as much as one third of the total volume of

car traffic in large cities. Shortening the search for parking would

therefore result in considerable fuel and emission savings in urban

areas, meaning that everyone benefits.

This advanced degree of digitalisation and connectivity is ushering

in a new generation of vehicles at BMW that will enjoy continuous

improvement during their life cycles. Since the introduction of the

modular BMW Operating System 7 vehicle software in 2018, BMW has been

offering extensive over-the-air Remote Software Upgrades for its

latest generation of models. As a result, BMW vehicles are always up

to date, no matter whether they are fresh off the production line or

already in action out on the road. The largest and most extensive

upgrade campaign in the company’s history got underway in mid-October

2020. More than 750,000 BMWs around the world are set to receive an

array of new functions and improvements, such as the cloud-based

navigation system BMW Maps and the integration of Android

AutoTM. This is the largest over-the-air update ever to

have been rolled out by a European manufacturer.

BMW Group to become the first premium manufacturer with 5G in

series production.

The BMW iX will now go one step further by becoming the first premium

model to be equipped with 5G mobile technology. 5G offers extremely

high data bandwidth and low latency – meaning fast data transmission –

and also expands the possibilities for connectivity between the

vehicle and its environment. It forms the basis for real-time

reception and transmission of data and sensor system information to

the BMW cloud. Together with the improved quality of service offered

by the 5G network, this will bring about significant enhancements and

innovations in the areas of entertainment, infotainment, automated

driving and road safety. The high data transmission rates will

additionally enable a far greater degree of cloudification. This

involves transferring vehicle functions requiring a lot of computing

power to the BMW cloud, where the combined performance of an entire

computing centre is available with the ability to process vast

quantities of data and complex tasks. The computed data is sent back

to the car in a matter of milliseconds courtesy of 5G.

This cellular mobile technology and, most notably, the 5G standard

also have the potential to connect vehicles with other road users.

C-V2X (Cellular Vehicle to Everything) solutions allow cars,

motorcycles, buses and trucks to communicate with one another, with

the smartphones of pedestrians, cyclists and scooter riders and even

with the infrastructure directly without any need to connect to the

mobile network. This enables information such as direction of travel

to be shared in specific traffic situations and warnings of potential

hazards to be transmitted.

5G is nothing less than the next level of connectivity and it

represents a crucial advance for mobility’s next evolutionary step.

More complex functions, simpler operation.

The increasing functionality and connectivity of vehicles and their

extensive digitalisation inevitably add to the complexity of the

overall system. By contrast, vehicle operation is becoming simpler,

more intuitive and more natural. This is made possible by increasing

levels of intelligence and function automation on the one hand, but

also through the deployment of shy tech and pared-down, clearly

arranged controls like those in the BMW iX. As vehicle intelligence

increases, more complex functions can be taken off the driver’s hands,

allowing the person at the wheel to focus purely on the essentials and

the pleasure of driving. If on-board intelligence is handling more

tasks and more information is being made available, this also means

that the vehicle is playing a more active role in the interaction

between human and machine. After all, in a mobility context, vehicles

sometimes know more than the driver: where the next free parking space

or fast-charging point is, for example, or that heavy rain is starting

to fall a few hundred metres further on, that a corridor for emergency

vehicles needs to be formed in a couple of miles, or that there is an

upcoming temporary speed limit due to moving roadworks – all

information that is relevant for the driver. What is crucial here is

that the right information is presented in the right place at the

right time, allowing the driver to react and interact in an

appropriate manner for the situation at hand. Interaction design at

BMW clearly focuses on multimodal operation using a combination of

physical controls and touch, voice and gesture control.

Accumulated digital expertise in development.

At the BMW Group, a team of digital experts strive for perfection as

they work together eagerly to integrate groundbreaking technologies

into a car and fuse hardware and software to harmonious effect. They

interconnect mobility and the digital world and turn the vehicle into

a highly integrated, integrative device that dovetails seamlessly with

the customer’s digital ecosystem.

The BMW Group operates with an international network of developers

stretching from China via Europe – through the Research and Innovation

Centre in Munich and Critical TechWorks in Portugal – to various sites

in the USA. This way, different skills and areas of technical

expertise and, most notably, the differing customer requirements of

each region are incorporated into the design and development phases.

The young team of more than 7,200 software and IT experts encompasses

a diverse range of disciplines, including software engineers, UX

designers, psychologists, data scientists, as well as specialists in

AI, robotics, autonomous driving and smart production. Agile work

processes and methods in workspaces that have been purpose developed

for collaboration lend themselves to short development and innovation cycles.

On average, 70 customer studies a year are conducted in relation to

interface design alone. These studies are an essential component of

customer-centric and data-driven development. They allow prototypes to

be continuously checked for user-friendliness and compared against the

customers’ mental model. Clear feedback is evaluated and subsequently

fed directly into the next development steps. Development also factors

in anonymised data from the vehicle fleet. The information from the

vehicles of customers who have actively consented to data being

transmitted is depersonalised and aggregated in order to provide a

picture of how the majority of users behave and how behaviour varies

in different regions of the world. Further customer-centric

development tools include specially designed dialogue formats as well

as trend scouting and research.

The overriding objective is to develop a system that is as easy and

intuitive to use as possible, suited to all customer groups and

therefore highly flexible and customisable.

Virtual collaboration

.

BMW Group is using technology from the gaming sector

.

What does gaming sensation Fortnite have to do with the BMW iX? It’s

a question that might leave even BMW connoisseurs and gaming experts

with a blank look on their faces. And yet the most successful computer

game of recent years – it recorded 350 million players in May 2020 –

and the BMW Group’s new technology flagship do indeed share common

ground: they used Unreal Engine from Epic Games in their development.

What may sound astonishing at first is, on closer inspection,

actually quite logical. After all, with the BMW iX embodying the dawn

of a new age in driving pleasure, a radical change in thinking was

needed in the development process. Existing engineering tools were no

longer fit for purpose given the car’s complex specification brief.

Added to which, BMW had set itself the goal of elevating the

functionality and user experience the BMW iX offers its customers to

unprecedented levels.

“We took the development of the BMW iX in totally new directions,”

explains Frank Weber, Member of the Board of Management of BMW AG,

Development. “For example, we used innovative technologies from the

gaming industry to visualise the interface between design and

technology as realistically as possible. The BMW iX is the first car

to be developed using the game engine we modified.”

Partnership with Epic Games.

These were two important reasons why BMW decided to rethink the

development of the BMW iX from the ground up. The company contacted

Epic Games back in 2015 – and it wasn’t long before it became the

first carmaker to introduce a mixed-reality system into the vehicle

development process in which components from the gaming industry

played a central role. The system is based on Epic Games’ Unreal

Engine 4, which also powers Fortnite and the racing simulator Assetto

Corsa Competizione.

“Today, gaming technologies offer many of the functions – for

example, virtual reality and the interaction between users – that we

are lacking in our engineering tools,” explains Matthias Oberhauser,

Product Owner Design and Virtual Product Experience BMW. “That’s why

we have taken a lead from gaming technology for this project. In 2015

a small team at BMW set about modifying the game engine so we could

use it in vehicle development.”

The tech duly saved a considerable amount of time and money in the

early development stages, in particular. Before this system started

work, virtual reality testing was only possible with the help of

expensive, specialised equipment. Using consumer electronics gave the

developers a previously unimagined degree of flexibility, as they

could implement and test changes extremely quickly. In addition,

developers around the world could get involved in decision-making from

wherever they happened to be, removing the need to travel long

distances. Only when designs have been assessed in virtual reality and

using 3D glasses are they turned into physical models for further testing.

“When BMW came to us, we were surprised at first,” recalls Doug

Wolff, Business Development Manager, Manufacturing Epic Games. “But

then we were really excited about the idea of using innovative

technologies from the gaming sector in vehicle development –

especially at the interface between design and technology. You can

certainly say that BMW leads the way in both the automotive industry

and beyond when it comes to collaboration tools based on game engines.”

Mixed reality assists BMW iX development.

However, BMW went a step further in the development of the BMW iX. An

example here is its use of technology for the car’s spectacular

interior. As visual impressions are often not sufficient in this area,

BMW employed a reusable interior design. The use of rapid prototyping

– a fast-paced process for manufacturing sample components – adds a

mixed-reality dimension to the development process. I.e. it benefits

from the intelligent combination of surfaces you can actual feel and

control elements presented using virtual reality.

The result is an all-encompassing experience enhanced even further by

accurate reproduction of the signature BMW engine sound, for example.

Using the virtual reality model allows the vehicle to be experienced

in a variety of environments. The totally realistic vehicle impression

created in this way is currently unique in the automotive industry.

The ability to present vehicle functions and new interior concepts

extremely quickly by means of these visual experiences in the virtual

reality space opens up various new avenues – for example, simulation

of journeys through cities. Here, it is possible to test aspects

including visibility over the area around the car and to check how

different viewing angles and seating positions affect the view of a

display on a screen or how difficult it is to reach. This gives the

development engineers the impression of experiencing a real-life road

situation inside an actual car.

BMW Group extends use of gaming technology into other areas of

the company.

The BMW iX is the first car to have been developed at BMW using

gaming technology. It meant the engineers and designers were not only

able to assess the static geometry of the car, they could also

experience the BMW iX and all its functions virtually at every stage

of the development phase.

However, for BMW this is only the beginning. The potential of gaming

technology for future projects is enormous; it is capable of

revolutionising not only vehicle development but also other areas,

such as design, production and sales/marketing. Indeed, the BMW Group

is already employing the short development cycles of consumer

technology in many other areas of the company. And it has now

developed the technology into a platform which is used in almost all

processes and is being further expanded. Other BMW projects – such as

factory planning and sales organisation – are now learning and

benefiting from the experiences gained in the production of the BMW iX.

Artificial intelligence

.

The basis for automated driving and natural interaction

.

The BMW Group currently employs artificial intelligence (or “AI” for

short) in more than 400 applications and in every relevant area of the

company. Development is one example; here AI provides the basis for

automated driving and the most natural possible in-vehicle user

experience. “Artificial intelligence plays a central role at the BMW

Group,” says Simon Euringer, BMW Group, Head of Intelligent Personal

Assistant. “It helps us with the processing and interpretation of

large quantities of data – whether that’s in sales, production or research.”

Extensive data pool provides the basis for all AI applications.

Artificial intelligence requires an extensive pool of data, whatever

the application. In order to virtually reproduce driving situations at

the Driving Simulation Centre and, in the next step, train BMW Group

vehicles for automated driving, the actual road network and traffic

situations first need to be digitalised.

The basis for data-driven development therefore consists of the data

collected worldwide by the vehicles of the BMW Group Automated Driving

Test Fleet, plus – since the end of 2019 – the data from vehicles

owned by BMW Group customers, who have consented to this anonymised

information being transmitted and processed.

As of October 2020, this already equates to over 250 million

kilometres of real-world driving experience from the regions of Europe

and North America. From the totality of data from these two sources –

the BMW fleet and BMW customer vehicles – particularly relevant

driving scenarios and environmental factors are selected and their

relevance is continuously increased.

Particularly challenging scenarios for AI-based simulations are, in

turn, extracted from this to ensure that the intricacy of reality is

taken into account as fully as possible in the development of complex

driver assistance systems like the Driving Assistant Professional and

future automated driving applications.

These vast quantities of data are processed by the BMW Group High

Performance D3 platform with over 230 petabytes of storage

capacity (in the planned expansion) and an extremely powerful computer

platform with more than 100,000 processor cores and over 200 GPUs

(Graphics Processing Units).

The development of automated driving with the

BMW iX.

AI creates an algorithm based on the data collected, and this then

calculates safe and anticipatory automated driving functions. So

without AI, automated driving cannot progress. All of the results of

the calculations are tested directly at the BMW Group Autonomous

Driving Campus in Unterschleißheim, which is connected directly to the

BMW Group High Performance D3 platform located just a few

kilometres away by high-performance fibre-optic cables.

In the future, the BMW iX will play an important role in the ongoing

development of automated driving. “With its all-new technology

toolkit, its computing power, high-performance sensor technology,

highly advanced data-driven development and embedded AI for processing

complex tasks, the BMW iX offers the potential to continue developing

automated driving functions year after year,” says the BMW Group’s

André Roskopf, an expert in data-driven development and AI.

AI can already be experienced in BMW vehicles.

Artificial intelligence can already be used and experienced by

drivers and passengers in BMW Group vehicles. The Intelligent Personal

Assistant (IPA) – available in a large number of models since the end

of 2018 – employs AI to make it easier for customers to use functions

in their vehicle. The driver activates the IPA using the prompt

“Hey BMW” and can operate a host of functions by voice control without

having to use pre-defined commands. “The key here is AI and machine

learning. These are indispensable elements of natural interaction –

i.e. intuitive vehicle operation – and enhance both the comfort and

safety of those on board,” explains Simon Euringer.

Driving Simulation Centre

.

The new benchmark for the automotive industry

.

When the BMW Group was planning its all-new Driving Simulation

Centre, the technology the company decided to use included

supercapacitors, direct drive with linear motors and 360-degree

projectors. At the same time, the entire planning process was made

customer-centric. The outcome is a Driving Simulation Centre that sets

new standards.

“With 14 simulators on a site measuring 11,400 m² in total, our new

Driving Simulation Centre in Munich is the most advanced and

diversified facility in the automotive industry,” says Frank Weber,

Member of the Board of Management of BMW AG, Development. “Here,

simulators with a wide range of motion systems are being built – all

the way up to highly dynamic units that use direct drive with linear

motors to recreate a realistic BMW driving experience. This takes us

to a new level of virtual development.”

Building work in Munich began in 2018 and the new Driving Simulation

Centre will be put into operation gradually. Here, the BMW Group is

turning the most progressive concept in the automotive industry into

reality. The company is creating every opportunity for its vehicle

research and development engineers to simulate and test the product

requirements of the future under realistic conditions.

Optimum simulation tools for every stage of development.

The new Driving Simulation Centre will provide the ideal simulation

tool for every area and every phase of the vehicle development

process. At the same time it will take customer involvement in the

development process to a whole new level. “We can perform test drives

for studies with up to 100 test persons per day,” says Michael

Brachvogel, Head of BMW Group Research, Interiors, User Interaction,

User Experience and Driving Simulation, who involves not only BMW

Group engineers but also external test persons in the virtual test

drives. “The new Driving Simulation Centre makes an enormous

contribution to our customer-centric product development. We can

integrate direct customer feedback into the development process at any

given moment.”

Virtual experience of every last detail.

For years now, driving simulation has played a key role in the

driving dynamics segment of the development function at the BMW Group.

The new Driving Simulation Centre will enable the virtual development

process to be further expanded, thereby reducing the number of

prototypes that need to be built as well as the duration of the

development cycle. “Both in the early phase of development and at the

validation stage, every nuance that goes to make up that signature BMW

driving feeling can be sampled in the state-of-the-art simulators,”

says Thomas Lachner, a driving simulation expert with the driving

dynamics development team.

The Driving Simulation Centre is the perfect response to the

ever-increasing requirements facing the development of intelligent,

highly connected vehicles. New display and control concepts can be

subjected to intensive tests, for example to analyse the risk of

driver distraction or the effectiveness of the multi-modal controls.

“With the aid of extensive tests in the driving simulator we can

design our systems in such a way that our customers in their vehicles

obtain the right information at the right time and in the right place

– all in the most intuitive way possible and in every conceivable

driving situation,” says Marion Mangold, team lead User Interaction Concept.

Traffic scenarios that involve risk or occur only rarely are almost

impossible to test on the road. So driving simulation offers major

advantages, in particular for the development of driver assistance

systems and functionalities that will in future be automated. In the

simulator, these kinds of situations can be replicated safely and in

great detail as often as required. “Our preparations for the

introduction of our driver assistance functions are extremely

thorough. Driving simulation is a major factor in ensuring that we can

develop the best and safest products for our customers,” says Manuela

Witt, expert for Safety-in-Use and Effectiveness Analysis.

Total immersion in seamless simulation.

The Seamless Simulator Experience was conceived by the BMW Group’s

simulation experts with the aim of immersing test persons much more

deeply in virtual driving situations. For example, in selected studies

test persons wearing a VR headset will in future make their way from a

virtual BMW or MINI dealership to the vehicle waiting outside for a

test drive. They only remove the headset immediately before entering

the simulator. This leads to a very high level of immersion. “This way

we get very valid and robust results for the optimisation of our user

functions,” says Martin Peller, overall project manager of the new

Driving Simulation Centre.

High-end simulators use direct drive with linear motors for a

realistic BMW driving experience.

In the high-fidelity simulator, driving scenarios are reconstructed

in great detail and with high precision. This means that, for the

first time, complex urban driving situations – which present a

particularly wide range of challenges for automated driving systems –

can now be replicated under laboratory conditions. In this simulator’s

almost 400-square-metre motion area, longitudinal, transverse and

rotational movements of a vehicle can be represented simultaneously.

The simulator is capable of putting a total mass of 83 metric tons

through maximum acceleration of 0.65 g. For its part, the High Dynamic

Simulator – the second highlight of the new Driving Simulation Centre

with a 21-metre sled and a moving mass of 23 metric tons – can

generate longitudinal and lateral acceleration of up to 1.0 g. It

permits the replication of highly dynamic evasive action, emergency

braking and hard acceleration.

These two high-end simulators move on a sophisticated system of

wheels and rails, which reacts virtually instantaneously to driver

inputs such as steering commands. Acceleration is provided by linear

electric motors with no moving parts. These hover above a series of

magnets, using much the same technology as maglev trains.

Supercapacitors deliver the peak power required by the motion system

in fractions of a second, while regenerative braking is used to

resupply them with energy.

Further information on the Driving Simulation Centre can be found by

following this link:

https://www.press.bmwgroup.com/global/article/topic/5236/technology/

BMW iX.

The dawn of a new era

.

The BMW iX is the BMW Group’s new technology flagship. It opens the

door to the next level in all-electric driving pleasure and, in the

process, ushers in a new age of mobility focused on a reinterpretation

of design, sustainability, driving pleasure, versatility and luxury.

Due to come onto the market at the end of 2021, the BMW iX is

currently in the final phase of development. It takes all of the

knowledge, experience and innovations amassed by BMW – the leading

premium supplier in the field of electric mobility – over recent years

to a new high point. This is the first BMW model to be based on an

all-new technology toolkit and was conceived from day one for purely

electric mobility.

“The BMW Group is constantly striving to re-invent itself. That is a

central element of our corporate strategy,” says Oliver Zipse,

Chairman of the Board of Management of BMW AG. “The BMW iX expresses

this approach in an extremely concentrated form.”

Fifth-generation BMW eDrive technology delivers outstanding

efficiency and high range.

The new era of mobility will unfold at BMW Plant Dingolfing from

2021. The BMW iX leads the way with future technologies that will also

be incorporated into other BMW models in the foreseeable future. At

the heart of the BMW iX is the fifth generation of BMW eDrive

technology, which encompasses the car’s two electric motors, its power

electronics, charging technology and high-voltage battery. The power

unit was developed by the BMW Group and is manufactured in a

sustainable production process without the use of critical raw

materials known as rare earths. According to the latest predictions,

its maximum output will exceed 370 kW/500 hp, with 0 – 100 km/h (62

mph) possible in under 5.0 seconds.

The drive system delivers not only impressive driving dynamics but

also a combined electric power consumption figure of less than 21 kWh

per 100 kilometres in the WLTP test cycle (the most relevant method at

market launch). This is exceptionally low for its segment. With a

gross energy content of more than 100 kWh, the latest-generation

high-voltage battery enables a range of over 600 kilometres in the

WLTP cycle. That equates to more than 300 miles according to the EPA’s

FTP-75 test procedure. (All figures relating to performance, energy

consumption and range are predicted values based on the car’s current

stage of development.)

DC fast charging at up to 200 kW allows the battery in the BMW iX to

be replenished from 10 to 80 per cent of its full capacity in just 40

minutes. Stopping off at a fast-charging station allows users to top

up the car’s range by more than 120 kilometres (75 miles) within ten minutes.

The batteries fitted in the BMW iX are designed as part of a

long-term resource cycle and enable an exceptionally high recycling

rate. “Technology is driving the advances we need to tackle even the

greatest challenges. This applies in particular to climate

protection,” says Oliver Zipse. “We are firmly convinced that mobility

has to be sustainable if it is to represent a truly outstanding

solution. For the BMW Group, premium mobility is not possible without responsibility.”

Design for a new kind of mobility.

The BMW iX also raises the bar in terms of design. Its innovative use

of forms redefines the successful BMW Sports Activity Vehicle (SAV)

concept. Muscular exterior proportions, a flowing roofline and reduced

surfacing turn the locally emission-free model into an experience

space delivering comfortable mobility both in day-to-day use and over

longer journeys. At the same time, with dimensions roughly similar to

those of the BMW X5 and BMW X6, the BMW iX exudes a new kind of poise

and authority anchored in sustainability, driving pleasure and premium characteristics.

One visible symbol of the fusion of innovation and design at work in

the BMW iX is the new kidney grille design, which is fully blanked off

and performs a digital role as an intelligence panel. Camera

technology, radar functions and other sensors are integrated

seamlessly into the grille behind a transparent surface with a

three-dimensional pyramid structure. This provides the driver with

advanced assistance systems that pave the way for automated driving.

The surface of the kidney grille has a self-healing effect which can

repair minor scratches, for example, within 24 hours at room temperature.

Shy tech: the seamless and invisible integration of high-tech functions.

Users can sample the groundbreaking design of the BMW iX in most

depth when inside the car, although they begin to experience the “shy

tech” principle in play here while climbing aboard. Shy tech refers to

technology that remains largely in the background and only reveals its

functions when they are being used. On entry into the car, the

function in question is the electrically powered door locks. The

interior welcomes the occupants of all five seats with a luxurious

lounge-style ambience, and provides the space required to explore new

ways of using time spent inside the car.

The omission of the centre tunnel gives the cabin an airy and

spacious feel, and ensures passengers in the second row also enjoy

extremely generous legroom. This further accentuates the lounge-style

ambience and long-distance comfort provided by the interior.

The displays and controls are all stripped down to the essentials,

and the shy tech approach for the interior can be seen in a number of

features, including speakers that have been integrated out of sight,

intricately styled air vents, heated surfaces and the BMW Head-Up

Display’s projector, which is recessed discreetly into the instrument

panel. For the first time in a model from the BMW Group, there is the

option of integrating speakers into the seat structure. Meanwhile, the

hexagonally shaped steering wheel (making its debut in a BMW), a

rocker switch for gear selection and the BMW Curved Display that forms

part of the next-generation BMW Operating System clearly advertise the

futuristic form of driving pleasure on offer. The BMW Curved Display

is held in place by a supporting structure that is concealed from the

occupants’ view, so it appears to be standing freely in the cockpit.

This new technology takes the traditional driver focus of a BMW

cockpit to the next level, uniting the 12.3-inch instrument cluster

and 14.9-inch Control Display to form a single unit that curves

towards the driver.

“No other user interface on the market can be operated as simply and

as safely as ours,” says Frank Weber, Member of the Board of

Management of BMW AG, Development. “In the BMW iX we have taken this

to a new level with a new digital vehicle platform.”

Optimised aerodynamics and lightweight design for increased

range and efficiency.

As well as impressing in terms of design, sustainability, driving

pleasure and premium characteristics, the BMW iX also convinces with

the technology underpinning this new age of mobility at BMW.

Credit for the drive system in the BMW iX goes to the fifth

generation of BMW eDrive technology, which encompasses the car’s two

electric motors, its power electronics, charging technology and

high-voltage battery. BMW teams the eDrive tech with far-reaching

measures for optimising aerodynamic properties and minimising weight.

The interplay of these three factors enables even lower energy

consumption and therefore increased range. The handling qualities of

the iX and the level of comfort inside the cabin likewise benefit from

reduced drag and the car’s bodywork structure, with its aluminium

spaceframe and pioneering Carbon Cage.

The drag coefficient (Cd) of the BMW iX is just 0.25 – proof of its

outstanding aerodynamics. The driver experiences the tangible effects

of this aerodynamic efficiency most clearly in the form of

significantly increased range. The bespoke aerodynamics measures for

the front end, rear end, underbody and wheel areas alone succeed in

adding over 65 kilometres (40 miles) to the range of the BMW iX.

Further information on the BMW iX can be found by following this link:

https://www.press.bmwgroup.com/global/article/topic/12079/bmw-inext/

MINI Vision Urbanaut.

Make it your space.

When MINI presents the "MINI Vision Urbanaut" at 14:00 on

17.11.2020 at #NEXTGen , the brand will exclusively unveil its totally

new vision of space. There’s something to be excited about.

BMW Motorrad Definition CE 04.

"Plugged to Life” – a new form of urban two-wheel mobility

.

With its electric drive system, trailblazing design and innovative

connectivity solutions, the BMW Motorrad Definition CE 04 is setting

out to change the face of the scooter segment as we know it. This

close-to-production further development of the BMW Motorrad Concept

Link links the customer’s analogue and digital worlds under the banner

“Plugged to Life” and doubles up as a means of transport and

communications hub for city commuters. Add intelligent rider equipment

to the mix and the result is an all-embracing, emotionally engaging

and newly conceived mobility experience.

As Edgar Heinrich, Head of Design at BMW Motorrad, explains:

“Electric mobility is a key form of drive system for the BMW Group and

we are employing this technology consistently in our sustainability

strategy. Electric drives are also a relevant topic for BMW Motorrad,

especially for the urban environment. Since 2013, we have been a

pioneer in this area with the BMW C evolution scooter. The BMW

Motorrad Definition CE 04 is the logical continuation of the electric

mobility strategy for urban centres and provides a concrete preview of

what a near-production bike for taking two-wheeled electric mobility

in cities to a new level – both technically and visually speaking –

might look like.”

Innovative architecture and pioneering design.

The segment-shaping design of the Definition CE 04 embodies a new

urban aesthetic and stylistic evolution. Many innovative elements and

details of the BMW Motorrad Concept Link – which was seen as a radical

vision for the distant future back in 2017 – are now approaching

production readiness. The technical composition of the electric drive

system enables groundbreaking design that responds to the fundamental

requirements of today’s users in terms of straightforward

functionality, a clear aesthetic and their digital reality, and

represents a departure from established scooter styling. Clear lines,

large surfaces in Mineral White metallic and precise forms create

modern proportions. The two-tone colour split adds to this impression.

The technical heart of the Definition CE 04 – made up of the drive

system, single-sided swing arm, spring strut and tooth belt – is

painted matt black. Plus, the slim batteries in the underfloor section

and the compact drive unit on the rear wheel offer scope to explore

new avenues. The side-access compartment (which can accommodate a

helmet, for example) is a case in point. The lower centre of gravity

brought about by the low-mounted battery pack ensures playful handling

and dynamic riding pleasure.

Practical and ergonomic.

The drive unit and battery pack are designed for a practical everyday

bike designed to transport users from home to workplace, or to evening

get-togethers with friends. The urban target customers mainly travel

short distances of approximately 12 km (7.5 miles) each day, so

although the seat should be comfortable it does not require

particularly heavy padding. Cue the floating bench design, which also

allows riders to climb on easily from the rear and improves ergonomics

for single riders, regardless of their leg length or body size.

Connecting the rider with their surroundings.

The BMW Motorrad Definition CE 04 also shines the spotlight on

practical and user-oriented solutions when it comes to digital

applications. BMW Motorrad sees significant future potential in the

interaction between the rider and their equipment in terms of safety,

comfort and the emotional experience on board. For example, the rider

can connect with their surroundings via a combination of the BMW

Motorrad Definition CE 04 and their smartphone. The 10.25-inch display

is the largest of its kind so far in the scooter segment and serves as

an interface between the rider’s analogue and digital worlds.

Rider equipment joins the outward communications toolkit.

The new rider equipment also enhances connectivity. And if desired,

it can even help the scooter communicate with its surroundings. The

clothing range developed exclusively for the BMW Motorrad Definition

CE 04 centres on a casually cut warm parka designed for everyday use.

Light guides integrated into the sleeves and hood provide improved

visibility on the road. They are activated by sensors in the sleeves

and can change colour.

To ensure the rider remains contactable at all times, the parka’s

inside pocket has an inductive smartphone charging panel. The rider

equipment therefore slips seamlessly into the user’s life and has a

cool look which is both urban and extremely practical. The new range,

which also includes black riding jeans, stylish sneakers and a white

open-face helmet, allows the rider to climb off the bike easily and

get on with their day. As well as being extremely comfortable to wear,

the rider equipment naturally also offers the protection riders expect

from BMW Motorrad and even becomes part of on-bike outward communications.

Graphics as a unique styling feature.

The unobtrusive graphic design showcases the new concept to optimum

effect. Completely different design variants are also conceivable that

allow customers to express their personality – from modern elegance

through to an urban look.

Further information on the BMW Motorrad Definition CE 04 can be found

by following this link:

https://www.press.bmwgroup.com/deutschland/article/topic/8498/design-konzepte-studien/

#NEXTGen Voices.

At the cutting edge of development.

For a company such as the BMW Group, being at the cutting edge of

development involves far more than just assuming a leading role in

automotive production. It also means setting trends in numerous other

fields and staying receptive to new movements and customer requirements.

Drivers for Change: a talk about leading transformation

.

The automotive industry is currently in a period of transformation

that the BMW Group is actively driving. Vehicles such as the BMW iX,

the MINI Vision Urbanaut and the BMW Motorrad Definition CE 04 are all

outward signs of this. For a company with a global presence, however,

this transformation is far more profound and impacts not just

products, production and process chains, but the individual employees too.

The “Drivers for Change” talk being held as part of #NEXTGen 2020

will highlight how leadership drives change. Steffi Czerny, co-founder

and Managing Director of Digital Life Design (DLD), will be the host

of this panel with Member of the Board of Management of BMW AG for

Human Resources and Labour Director Ilka Horstmeier and Marie Langer,

CEO of EOS GmbH, as they discuss transformation, what it means, how to

guide it and the opportunities it presents. Discussion topics will

also include the role of motivation and inner conviction in the

forthcoming transformations.

A new form of sport – BMW’s involvement in esports.

BMW has always been a true global player when it comes to

partnerships and involvement in sport. In 2020, the company stepped up

its presence in the world of esports to add arguably the most exciting

sporting discipline of the moment to its portfolio. This includes

partnership deals with some of the major esports teams as well as

fielding a strong BMW squad in the fast-growing esport of sim racing.

The focus here is always on the protagonists. Under the campaign

slogan ‘United in Rivalry’, for example, BMW is partnering with the

Cloud 9 (US), Fnatic (UK), FunPlus Phoenix (CN), G2 Esports (DE) and

T1 (KR) teams as they do battle in the hugely popular League of

Legends World Championship. The company is appealing directly to

younger target groups with an all-new approach and posting some

exceptional storytelling on BMW’s esports social media channels. One

milestone along the way was the “Berlin Brawl” in August, which saw G2

Esports and Fnatic go head-to-head, interact with their fans and

create a digital buzz.

“As with all our sporting commitments, we will be supporting the

discipline as a whole and helping it evolve in our role as global

esport partner,” says Jens Thiemer, Senior Vice President Customer and

Brand BMW. “This is a long-term development we are fully committed to.

We’re here to stay.” The same applies to the company’s involvement in

virtual motor sport with BMW Motorsport SIM Racing. The digital

replicas of racing machines such as the BMW M8 GTE, BMW M2 CS Racing

and BMW M4 GT4 take centre stage at BMW Cup events held on various

simulation platforms. The highlight of the season, taking place on 5

December 2020, will be the BMW SIM LIVE event, in which the most

successful SIM racers of the year do battle for prize money of over

30,000 US dollars.

Both in SIM racing and other esports, BMW highlights the sporting

angle above all. “We want to not only develop esports as

entertainment, but also establish it as a genuine sport,” says

Thiemer. “Part of this involves impressing on the participants that

physical and mental fitness are extremely important factors. The time

they spend at their PC or console has to be suitably measured.

Responsible use of time online is equally as important as preventing

addiction and getting the physical balance right.”

These issues will join a list of other topics concerning BMW’s latest

sporting involvement on the agenda when the brand hosts a major

meeting of the esports industry entitled “BMW Esports Boost” at BMW

Welt on 12 April 2021. A string of new announcements are in store,

along with fascinating meetings between some of the major esports

stakeholders. And fans will also play an important role at this event.

It is precisely this direct contact with a young audience that is so

important to BMW. “With esports, we are coming into contact with a

young and dynamic community which is growing all the time around the

world,” adds Thiemer. “We’re aiming to get young people excited about

BMW. And we do that by creating new touchpoints with our brand, making

ourselves visible and interacting with the community.”

Lifestyle on four wheels: the BMW M4 Competition x KITH.

BMW M GmbH has launched a collaboration with New York lifestyle label

Kith to help it sense new trends in a young and influential part of

the fashion scene. The BMW M4 Competition x KITH has been co-created

with Kith founder and BMW enthusiast Ronnie Fieg and features truly

unique exterior and interior design details. It will be built in 2021,

with production limited to just 150 units. Kith will also be offering

a 96-piece collection of exclusively designed apparel and accessories

in all of its stores and online. Deliveries of the limited

special-edition model will commence in summer 2021.

New, merged logos are a hallmark of the partnerships Kith has forged

with other globally renowned companies. And now BMW has also – for the

first time – altered its badge for a collaboration partner. For the

150 units of the BMW M4 Competition x KITH, an extra ring was added

around the familiar BMW roundel in the BMW M colours light blue, dark

blue and red. Plus, there are details in bright lettering focusing on

Kith and the collaboration. The M4 Competition badge served as the

template for a KITH logo also featuring the BMW M stripes. This can be

woven into the surface of the special-edition model’s carbon-fibre

roof as an extremely eye-catching option.

Available to order in the colours Frozen Black, Frozen Dark Silver

and Frozen Brilliant White, the special-edition model is based

technically on the BMW M4 Competition Coupé (fuel consumption

combined: 10.2 l/100 km [27.7 mpg imp]; CO2 emissions

combined: 234 g/km*). The most distinctive changes are found inside

the cabin. Exclusively designed features include the tri-colour

M Carbon bucket seats with detailing in light blue and red, as well as

the embossed KITH lettering in black leather on the head restraints

and centre armrest.

Further information on the BMW M4 Competition x KITH can be found by

following this link:

https://www.press.bmwgroup.com/global/article/detail/T0319271EN/

Leaping into a new dimension: The Electrified Wingsuit by BMW i.

When visionary power is brought together with innovative spirit,

great things can happen – like the leap into a new dimension with The

Electrified Wingsuit by BMW i. Following three years of preparation

and with the active support of BMW i and BMW Group company

Designworks, Austrian base jumper and wingsuit pilot Peter Salzmann

made the world’s first ever flight by a human wearing an electrically

powered wingsuit. BMW i was very receptive to Salzmann’s idea of using

a lightweight electrically driven impeller – a type of shrouded

propeller – in order to attain higher speeds during wingsuit flights

and also regain height while flying.

The engineers from BMW i brought all their expertise and experience

in electric mobility and battery technologies to bear, while the

Designworks experts were also involved from the outset, helping with

both the development of the fly unit – which featured two carbon-fibre

impellers, each with an output of 7,500 W at approx. 25,000 rpm and

around five minutes’ worth of peak combined output (15 kW) – and the

design of the wingsuit. Extensive testing in the BMW Group’s wind

tunnels subsequently allowed the necessary fine-tuning to be carried

out and confirmed that the idea worked.

The result is The Electrified Wingsuit by BMW i, which enabled

Salzmann to fulfil his dream of elevating wingsuit flying to new

heights – in a very efficient, sustainable, quiet and generally

astounding way. Peter Salzmann epitomises the BMW i ethos to

perfection with his ideas, passion and courage. The Electrified

Wingsuit by BMW i demonstrates what electric power is capable of and

proves that the future is electric.

Further information on The Electrified Wingsuit by BMW i can be found

by following this link:

https://www.bmw.com/en/innovation/peter-salzmann-electrified-wingsuit.html?tl=grp-opre-ngpc-brnd-mn-.-.-.-.-

Seeking a Vision for 2040: #NEXTGen Moving Tomorrow Pitch.

At #NEXTGen 2020, the BMW Group will also be taking a look into the

distant future in search of a Vision development for mobility in 2040.

To this end, the company invited entries for the #NEXTGen Moving

Tomorrow Pitch from students, research assistants and professors at

top universities and research institutes all over the world. The aim

is to find the interdisciplinary team with the best vision for

sustainable and individual premium mobility in the year 2040.

The BMW Group has chosen three finalists from the entries submitted.

Two teams from Tsinghua University in China and one from the

Fraunhofer Institute in Germany will be presenting their visions at

#NEXTGen 2020 in Munich in a video lasting no more than five minutes

followed by a live two-minute Q&A session on Skype with the panel

of three judges. The panel will consist of Ilka Horstmeier, Steffi

Czerny and Dr. Andreas Rickert, CEO and founder of PHINEO. The winning

team, who will be announced by the judges straight after the

presentations, will have an exclusive opportunity to meet top

BMW Group executives as well as receiving €15,000 in prize money.