PressClub Canada · Article.

Seven principles for AI: BMW Group sets out code of ethics for the use of artificial intelligence.

Mon Oct 12 09:00:00 CEST 2020 Press Kit

+++ AI already widely used within the company +++ Over 400 use cases throughout the value chain +++ Code of ethics underpins the increased use of AI technologies +++

Press Contact.

Marc Belcourt

BMW Group

Tel: +1-905-428-5078

Fax: +1-905-428-5071

send an e-mail

Author.

Marc Belcourt

BMW Group

Related Links.

Munich. The use of artificial intelligence (AI) is a central element of the digital transformation process at the BMW Group. The BMW Group already uses AI throughout the value chain to generate added value for customers, products, employees and processes.

Michael Würtenberger, Head of “Project AI”: “Artificial intelligence is the key technology in the process of digital transformation. But for us the focus remains on people. AI supports our employees and improves the customer experience. We are proceeding purposefully and with caution in the expansion of AI applications within the company. The seven principles for AI at the BMW Group provide the basis for our approach.”

The BMW Group continues to follow global developments in terms of both technological innovations and regulatory and ethical issues. Together with other companies and organisations, the BMW Group is involved in shaping and developing a set of rules for working with AI, and the company has taken an active role in the European Commission’s ongoing consultation process.

Building on the fundamental requirements formulated by the EU for trustworthy AI, the BMW Group has worked out seven basic principles covering the use of AI within the company. These will be continuously refined and adapted as required according to the multi-layered application of AI across all areas of the company. In this way, the BMW Group will pave the way for extending the use of AI and increase awareness among its employees of the need for sensitivity when working with AI technologies.

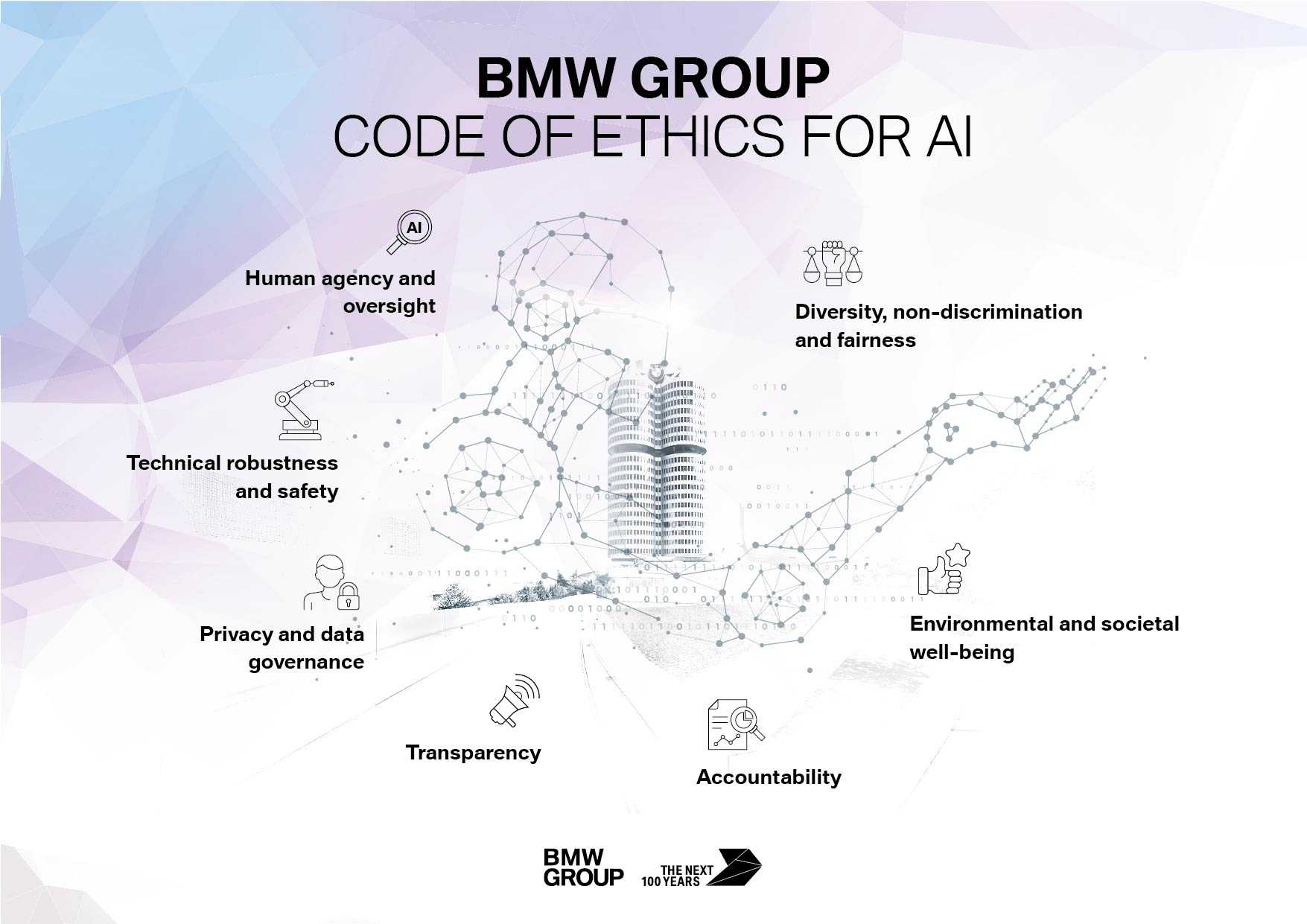

Seven principles covering the development and application of artificial intelligence at the BMW Group:

-

Human agency and oversight.

The BMW Group implements appropriate human monitoring of decisions made by AI applications and considers possible ways that humans can overrule algorithmic decisions.

-

Technical robustness and safety.

The BMW Group aims to develop robust AI applications and observes the applicable safety standards designed to decrease the risk of unintended consequences and errors.

-

Privacy and data governance.

The BMW Group extends its state-of-the-art data privacy and data security measures to cover storage and processing in AI applications.

-

Transparency.

The BMW Group aims for explainability of AI applications and open communication where respective technologies are used.

-

Diversity, non-discrimination and fairness.

The BMW Group respects human dignity and therefore sets out to build fair AI applications. This includes preventing non-compliance by AI applications.

-

Environmental and societal well-being.

The BMW Group is committed to developing and using AI applications that promote the well-being of customers, employees and partners. This aligns with the BMW Group’s goals in the areas of human rights and sustainability, which includes climate change and environmental protection.

-

Accountability.

The BMW Group’s AI applications should be implemented so they work responsibly. The BMW Group will identify, assess, report and mitigate risks, in accordance with good corporate governance.

Overall centre of competence for the company: “Project

AI”.

“Project AI” was launched in 2018 to ensure that AI

technologies are used ethically and efficiently. As the BMW Group’s

centre of competence for data analytics and machine learning, it

ensures rapid knowledge and technology sharing across the company.

Project AI therefore plays a key role in the ongoing process of

digital transformation at the BMW Group and supports the efficient

development and scaling of smart data and AI technologies. One of the

developments to come out of Project AI is a portfolio tool which

creates transparency in the company-wide application of technologies

making data-driven decisions. This D³ (Data Driven Decisions) portfolio

currently spans 400 use cases, of which more than 50 are available for

regular operation.

WHERE IS THE BMW GROUP ALREADY USING AI?

USE CASES FROM

DIFFERENT AREAS OF THE COMPANY.

The following examples show that Project AI pushes the BMW Group forward with AI focused, company-wide networking and knowledge transfer. The fundamentally identical technology forms of AI can generate added value for customers, employees and business processes. For example, the customer benefits from natural language processing (NLP) with the Intelligent Personal Assistant directly in the vehicle and employees are supported with translation tools and context-processing assistants in administrative processes. Intelligent data analysis and machine learning are used to optimise energy management both in buildings and in vehicles. And image processing AI relieves both the customer with driver assistance systems from monotonous driving tasks and employees in production from monotonous processing steps.

E XAMPLES FROM RESEARCH & DEVELOPMENT.

AI-based energy management in vehicles.

A

vehicle contains a large number of electric consumers, such as seat

heating, the entertainment system, the air conditioning, etc. In many

cases, the driver is not aware that using these consumers also has an

effect on CO2 emissions and/or the range of the vehicle. AI

experts at the BMW Group are conducting R&D work on AI-based

software for in-vehicle energy management. Taking user behaviour and

route information as a basis, the system learns how to adjust energy

consumption in the car as effectively as possible to the driver’s

requirements and the need for energy efficiency. In this way,

CO2 emissions can be reduced, energy saved and operating

range increased.

Acoustic analytics: sensory enhancement in the sensor model

for automated driving functions.

The BMW Group is

taking an all-encompassing approach to monitoring the vehicle

environment. One of the areas the company is exploring to this end is

how acoustic signal processing can be added to the AI sensor fusion.

Incorporating auditory perception can have benefits for urban

scenarios, in particular, going forward.

AI in requirements management.

At the BMW Group there are over 33,000 requirement specification

documents containing more than 30 million individual requirements for

vehicles, components and characteristics. That’s an enormous amount of

data. AI technologies can help employees to process large quantities

of data more quickly and carefully. Here, an application has been

developed which uses natural language processing methods to improve

the quality and analysis of individual requirements in specification

documents. The web-based tool allows thousands of requirements to be

automatically translated and checked – in real time – for linguistic

quality, similarity and consistency.

EXAMPLES FROM SUPPLY CHAIN MANAGEMENT AND LOGISTICS.

Integrating AI with facility and robot control systems.

The first smart AI control application at the BMW

Group celebrated its premiere at the BMW Group’s Steyr plant. This

application speeds up logistics processes by preventing the

unnecessary transport of empty containers on conveyor belts. To this

end, the containers pass through a camera station. Using stored image

data marked by employees, the AI application recognises if a container

needs to be lashed onto a pallet or whether – in the case of large,

stable boxes – no additional securing is required. If no lashing is

required, the AI application directs a container by the shortest route

to the removal station for the forklift truck.

Besides the application in Steyr, AI can be found in numerous other logistics innovations at the BMW Group. It also supports virtual layout planning, which creates high-resolution 3D scans of buildings and factories. AI ultimately contributes to the recognition of individual objects in the 3D scans, such as containers, building structures and machines. In this way, robotics applications out-perform the technology used previously in their coordination skills and ability to recognise people and objects. Navigation improvements enable obstacles such as forklift trucks, tugger trains and employees to be detected more quickly and clearly, and alternative routes to be calculated within milliseconds. The AI-based technology helps the robotics applications to learn and apply different reactions to people and objects.

EXAMPLES FROM PRODUCTION.

Since 2018, the BMW Group has been using various AI applications in series production. One focus is automated image recognition: In these processes, AI evaluates component images in ongoing production and compares them in milliseconds to hundreds of other images of the same sequence. This way, the AI application determines deviations from the standard in real time and checks, for instance, whether all required parts have been mounted and whether they are mounted in the right place. At the BMW Group, flexible, cost-effective, AI-based applications are gradually replacing permanently installed camera portals. Implementation is comparatively simple. A mobile standard camera is all that is needed to take the relevant pictures in the production hall. The AI solution can be set up quickly too. Employees take pictures of the component from different angles and mark potential deviations on the images. This way, they create an image database in order to build a neural network, which can later evaluate the images without human intervention.

Name plate checks.

In the final inspection area

at the BMW Group’s Dingolfing plant, an AI application compares the

vehicle order data with a live image of the newly produced car’s model

badge. Model designation badges and other identification plates (such

as “xDrive” for all-wheel drive vehicles and all generally approved

combinations) are stored in the image database. If the live image and

order data don’t correspond – if a designation is missing, for example

– the final inspection team receives a notification. You can find more

information here.

Dust particle analysis in the paint shop.

AI can control the operation of highly sensitive automotive

production equipment even more precisely, as a pilot project in the

paint shop at the BMW Group’s Munich plant has shown. If levels of

dust increase due to the time of year or a sustained dry period, the

algorithm picks up on the trend at an early stage and brings forward

the timing of a filter change, for example. Working in conjunction

with other analysis tools, additional patterns can be recognised.

Another result of the analysis might be that fine adjustments need to

be made to the machine using ostrich feathers to remove dust particles

from the car body. The BMW Group’s AI experts see great potential in

dust particle analysis. Supplied with information from numerous

sensors and data from surface inspection, the algorithm monitors more

than 160 features of the body and can predict the quality of a paint

application with great accuracy. You can find more information here.

AI control application in the press shop reliably prevents pseudo-defects.

At the press shop, flat sheet metal parts are turned

into high-precision components for the car body. Dust particles or oil

residues that remain on the components after forming can easily be

confused with very fine cracks, which occur in rare cases during the

process. Previous camera-based quality control systems at the BMW

Group’s plant in Dingolfing occasionally also identified these

pseudo-defects (deviations from the target values, but with no actual

fault). With the new AI application, these pseudo-defects no longer

occur because the neural network can access around 100 real images per

feature – i.e. around 100 images of the perfect component, 100 images

with dust particles, another 100 images with oil droplets on the

component, etc. This is particularly relevant in the case of the

visually close calls that have previously led to pseudo-defects. You

can find more information here.

BMW won the Connected Car Pioneer Award 2020 in recognition of its versatile use of AI in production.

EXAMPLES FROM AFTERSALES & CUSTOMER SERVICE.

AI at dealer service desks.

If a BMW customer

visits a dealer reporting a problem with their car, the problem needs

to be identified quickly and the right solution found reliably. To

help them do this, the service employee has the use of a knowledge

database, which has been expanded using a powerful software stack to

include both an intelligent and scalable search facility and AI (for

processing problem cases and knowledge data). AI incorporates context

information into the search process, enabling it to flag up identical

and similar cases. Added to which, an automatic translation function

breaks down the language barrier in the fault analysis process.

AI-based customer interaction in WeChat.

Chatbots help to significantly increase the quality and

availability of customer service. In China, BMW Financial Services

offers its customers an AI-based chatbot via the widely used WeChat

app. The chatbot allows customers to ask questions regarding their

personal finance agreement or make changes to their agreement. These

bots are first trained to deal with the topics for which most

questions are received by the call centre. If the chatbot cannot

answer a question, the enquiry is passed to a human member of staff.

This means that customers’ most frequently asked questions can be

answered quickly and with a consistently high level of quality around

the clock.

EXAMPLE IN BUILDINGS MANAGEMENT.

Increasing energy efficiency in BMW Group

buildings.

Since 2006 the BMW Group has been able to

consistently increase energy efficiency at its locations around the

world. It has now reached such a high level that identifying further

potential for improvement using conventional means is getting more and

more difficult. This is where the use of smart data and AI comes into

play. The BMW Group systematically processes all the energy-relevant

data at its locations so previously undiscovered energy consumption

patterns can be established using AI. Weather-related data can also be

incorporated into this process, enabling buildings to be heated and

cooled more intelligently and efficiently. In a pilot project in

Munich, this approach has allowed approximately 1,200 MWh of thermal

energy to be saved annually in the IT centre. This equates to the

energy consumption of approximately 60 family homes. This experience

and a rigorous process of data collection and analysis have also led

to positive energy efficiency results at office buildings such as the

BMW four-cylinder building, FIZ Projekthaus, Campus Freimann and the

dynamics centre at Dingolfing.

EXAMPLE FOR ADMINISTRATION & SUPPORT FUNCTIONS.

Customized Machine Translation (CMT) – machine translation

that learns the language of BMW.

The BMW Group is a

multinational company with a presence in over 100 countries. Its

customers, dealers and employees speak hundreds of languages and there

is an enormous daily influx of multilingual texts from external

sources. Human translation of all multilingual data does not make

sense due to the volume and costs involved. Freely available

translation solutions are not permitted for reasons of information

protection and often fail to provide the correct translation of

technical terms and formulations – the correct “BMW language”. With

this in mind, BMW Group IT has developed its own translation solution

specialising in BMW texts. BMW Group employees are now feeding over

2,000 sentences into the system every day.

EXAMPLES FOR CUSTOMER AND VEHICLE FUNCTIONS.

Driver assistance.

AI is the key to automated

driving – and is already present in current driver assistance systems

such as Driving Assistant Professional. Automation-based functions

help customers to drive safely, park and stay connected. On motorways,

they can take over longitudinal and lateral guidance of the vehicle

for extended periods. The customer remains responsible for the car,

but their task is now only to monitor what is happening.

BMW Intelligent Personal Assistant.

The BMW Group has revolutionised driving pleasure with the BMW

Intelligent Personal Assistant. Introduced in 2019, this intelligent

digital on-board companion responds to the prompt “Hey BMW”. The BMW

Intelligent Personal Assistant increasingly allows the car to be

operated, functions to be accessed and information obtained by voice

command alone. This technology enables direct communication and

natural interaction with the vehicle – helped by AI.

Article Offline Attachments.

-

BMW Group Code of ethics for AI - Long Version PDF, EN, 258.47 KB

-

BMW Group Code of Ethics for AI - Short Version PDF, EN, 249.38 KB